Top 10 Ways Industrial 5G Routers Enhance Remote Monitoring and Control

The ability to monitor and control assets from a distance is a cornerstone of modern industrial efficiency. While legacy solutions like wired networks, satellite, or early-generation cellular have enabled basic remote operations, they often come with limitations in speed, latency, cost, or flexibility. The advent of the 5G industrial router is fundamentally transforming this landscape, turning remote monitoring and control from a passive observation tool into an active, real-time driver of operational excellence.

Here are the top 10 detailed ways these robust devices are enhancing remote industrial operations.

1. Real-Time Telemetry and Control with Ultra-Low Latency

The Enhancement: Enabling truly instantaneous data exchange and command execution over vast distances.

The Details: For critical control systems, latency—the delay in data transmission—is the most important metric. 4G and wired broadband can introduce delays of 50ms or more, making closed-loop control risky. Industrial 5G, with its ultra-reliable low-latency communication (URLLC) capabilities, can achieve consistent latencies of 1-10ms. This allows for real-time telemetry from sensors (e.g., pressure, temperature, valve position) to be transmitted to a control center, where an algorithm or operator can send a command (e.g., “close valve,” “adjust RPM”) and see the result almost instantly. This makes remote control of delicate machinery, robotic arms, and safety systems not just possible, but reliable.

2. High-Definition Video Analytics for Predictive Maintenance and Security

The Enhancement: Adding a visual layer of intelligence through continuous, high-bandwidth video streaming.

The Details: Traditional remote monitoring relied on data points. 5G’s enhanced Mobile Broadband (eMBB) adds a powerful visual dimension. High-definition, real-time video feeds from cameras can be streamed continuously from remote sites to a central location. This video can be used for:

Visual Predictive Maintenance: AI algorithms can analyze video to detect visual anomalies like steam leaks, corrosion, or unusual equipment vibrations.

Remote Security and Safety: Live monitoring of perimeter fences, entry points, and worker safety compliance in hazardous areas without needing on-site security personnel.

This transforms monitoring from reactive (responding to a sensor alarm) to proactive (seeing a developing issue).

3. Unprecedented Network Reliability in Harsh Environments

The Enhancement: Ensuring a “always-on” connection for mission-critical systems, regardless of location.

The Details: Remote sites are often electrically noisy and physically harsh. Industrial 5G routers are engineered for this. They operate on licensed spectrum, which is protected from the interference that plagues Wi-Fi. Their ruggedized, fanless metal housings (often IP67 rated) withstand extreme temperatures, humidity, and vibration. This inherent reliability means that the vital link between the remote asset and the control center remains stable, ensuring that alarms are never missed and control signals are always received.

4. Massive Scalability for Distributed Sensor Networks

The Enhancement: Connecting thousands of endpoints across a wide area with a single, cohesive network.

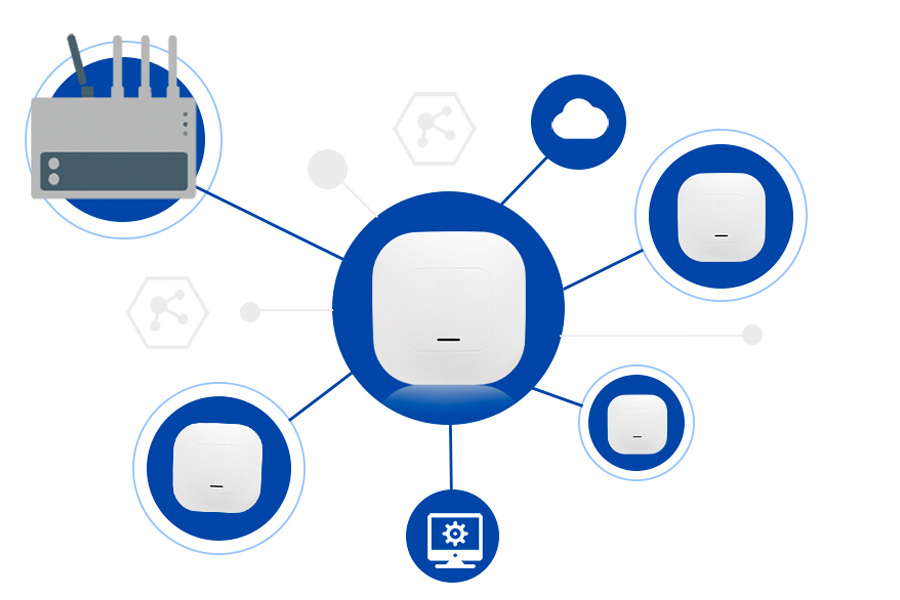

The Details: Modern remote monitoring involves dense networks of sensors. 5G’s Massive Machine-Type Communications (mMTC) capability is designed to support up to 1 million devices per square kilometer. This allows a single Industrial 5G router to act as a gateway for a vast array of wireless sensors monitoring everything from environmental conditions and energy consumption to equipment status across a large facility or a dispersed infrastructure network (like a water utility’s pump stations). This eliminates the need for complex and expensive wired connections to each sensor.

5. Rapid Deployment and Dynamic Reconfiguration

The Enhancement: Drastically reducing the time and cost to bring a remote site online or modify its connectivity.

The Details: Running fiber or copper to a remote oil well, a temporary construction site, or a newly acquired facility is time-consuming and expensive. An Industrial 5G router provides a “plug-and-play” solution. Once powered and authenticated, it establishes a secure, high-speed connection almost immediately. This agility also allows for dynamic reconfiguration; if a production line is moved or new monitoring points are added, the network can be adapted instantly without any physical rewiring, providing unparalleled operational flexibility.

6. Enhanced Security for Critical Infrastructure

The Enhancement: Providing a secure, encrypted, and manageable connection for sensitive operational technology (OT) networks.

The Details: Remote access is a major security concern. Industrial 5G routers address this with multiple layers of protection. The connection from the router to the core network is encrypted by default using advanced algorithms. Integrated features like stateful firewalls, VPN support (IPsec, OpenVPN), and the ability to create Private 5G networks ensure that remote SCADA and control system traffic is isolated from public internet threats and shielded from eavesdropping or manipulation.

7. Comprehensive Operational Awareness through Edge Computing

The Enhancement: Processing data locally to provide immediate insights and reduce cloud burden.

The Details: Transmitting raw data from thousands of sensors is inefficient. Many Industrial 5G routers now have built-in edge computing capabilities. They can run applications locally to filter data, perform initial analytics, and trigger immediate local actions. For example, the router can process vibration data locally, and only send an alert to the control center if a pre-set threshold is exceeded. This reduces latency for critical responses, minimizes cellular data costs, and prevents the central system from being overwhelmed by irrelevant data.

8. Robust Redundancy and Seamless Failover

The Enhancement: Guaranteeing operational continuity through automatic backup systems.

The Details: In remote monitoring, a single network failure can lead to catastrophic blind spots. Industrial 5G routers are designed with redundancy in mind. They often feature:

Dual SIM/Multi-Carrier Support: If the primary cellular provider fails, the router instantly fails over to a secondary provider.

WAN Failover: The 5G connection can serve as a backup for a primary wired line (or vice versa).

This multi-homed approach ensures that the connection—and therefore, visibility and control—is maintained under almost any circumstance.

9. Centralized Management of Geographically Dispersed Assets

The Enhancement: Providing a single pane of glass for overseeing an entire fleet of remote installations.

The Details: Managing dozens or hundreds of individual remote sites is a logistical nightmare. Industrial 5G routers integrate with cloud-based Network Management Systems (NMS). From a central dashboard, operators can see the health and status of every router, monitor data usage, push configuration and firmware updates, and receive instant alerts if a device goes offline. This centralized control drastically reduces the need for costly truck rolls and allows a small team to manage a vast, geographically dispersed operation efficiently.

10. Enabling the Transition to Autonomous Operations

The Enhancement: Providing the foundational connectivity for self-optimizing, unmanned systems.

The Details: The ultimate goal of remote monitoring and control is full autonomy. The combination of high bandwidth, low latency, and supreme reliability provided by Industrial 5G routers makes this possible. They are the communication backbone for:

Unmanned Autonomous Vehicles (UAVs/UGVs): For inspections in hazardous environments.

Fully Automated Industrial Sites: Where control systems self-optimize based on real-time sensor data without human intervention.

By providing a nervous system that is fast, reliable, and intelligent, these routers are paving the way for the fully autonomous industrial operations of the future.

Conclusion

An industrial 4g router is far more than just a connectivity upgrade. They are a strategic enabler that transforms remote monitoring from a simple data-gathering exercise into a powerful system for real-time control, predictive analytics, and operational resilience. By delivering a potent combination of speed, reliability, security, and intelligence to the farthest edges of the industrial world, they are breaking down the barriers of distance and creating a new paradigm where every asset, no matter how remote, can be seen, understood, and controlled as if it were right in front of you.