How a PCB Board Manufacturer in Singapore Ensures Quality and Compliance

Electronics production demands accuracy, consistency, and strict adherence to standards. A reliable PCB board manufacturer in Singapore must manage quality and compliance across every stage of production, from design to final inspection. This responsibility extends beyond fabrication alone, as collaboration with a PCB layout company plays a critical role in ensuring boards meet performance, safety, and regulatory expectations.

Embedding Quality Control From Design to Fabrication

Quality begins at the design stage, where a PCB layout company ensures layouts support manufacturability and long-term reliability. Layout decisions such as trace width, spacing, thermal relief, and component placement directly affect fabrication success. When layout engineers follow established design-for-manufacturing guidelines, they reduce production errors and improve yield rates. Early alignment between layout teams and manufacturers prevents costly revisions during fabrication.

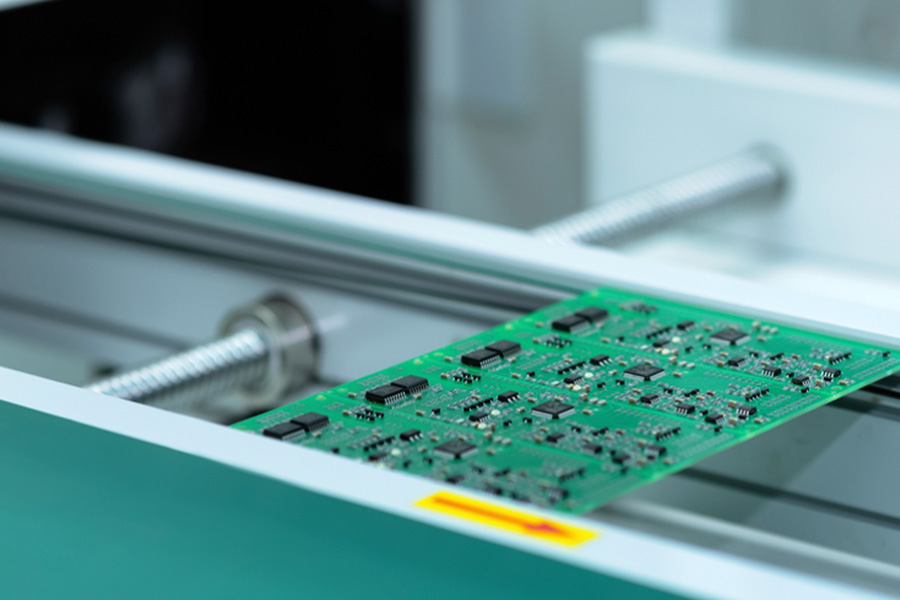

A PCB board manufacturer in Singapore then integrates quality controls throughout fabrication. Material selection, controlled lamination, precise drilling, and accurate etching ensure structural and electrical consistency. Manufacturers rely on calibrated machinery and standardised workflows to maintain tight tolerances. In-process inspections identify defects early, allowing technicians to correct issues before they compromise the final product.

Design Reviews That Improve Manufacturability and Yield

Design reviews form a key quality checkpoint. Manufacturers often work directly with a PCB layout company to conduct detailed design-for-manufacturing assessments. These reviews highlight potential risks such as signal interference, soldering challenges, or thermal stress points. Addressing these issues at the layout stage improves manufacturability and reduces production delays.

Companies like MPN Tech demonstrate the value of integrating layout review with manufacturing expertise. By aligning layout recommendations with fabrication capabilities, manufacturers help customers transition smoothly from prototype to mass production. This collaboration improves yield rates, reduces rework, and ensures boards meet both performance and compliance standards

Regulatory Compliance Supported by Design Expertise

Compliance with international standards starts at the layout level. A professional PCB layout company designs boards to meet IPC, RoHS, and ISO requirements, ensuring compliance before production begins. Layout engineers consider creepage distances, insulation requirements, and thermal constraints to align designs with regulatory expectations. This proactive approach reduces the risk of non-compliance during audits or market entry.

A PCB board manufacturer in Singapore reinforces this effort by maintaining documented processes and traceability systems. Manufacturers record material certifications, inspection data, and production parameters for every batch. This documentation supports regulatory audits and provides customers with confidence in product safety and consistency. Close coordination between layout teams and manufacturers ensures compliance remains consistent across revisions and production runs.

Testing and Inspection Guided by Layout Intent

Testing strategies depend heavily on layout design. A PCB layout company designs boards with test points and inspection access in mind, enabling efficient electrical testing. This foresight allows manufacturers to validate continuity, insulation resistance, and signal integrity without compromising board structure. Well-planned layouts reduce testing complexity and improve accuracy.

Manufacturers combine automated optical inspection with electrical testing to verify performance. Automated systems detect visual defects, while electrical tests confirm functional integrity. Skilled technicians review results and address anomalies quickly. This layered inspection approach ensures each board performs as intended under real operating conditions.

Continuous Improvement Through Design-Manufacturing Alignment

Long-term quality depends on continuous improvement and collaboration. Manufacturers analyse defect trends and share feedback with the PCB layout company to refine future designs. This feedback loop strengthens design standards and reduces recurring issues across projects. Regular training keeps teams updated on evolving technologies and compliance requirements.

A PCB board manufacturer in Singapore that prioritises design alignment, skilled personnel, and process optimisation remains competitive in demanding markets. Continuous collaboration between layout specialists and manufacturing teams ensures consistent quality, regulatory compliance, and reliable product performance.

Conclusion

Quality and compliance rely on strong coordination between a PCB board manufacturer in Singapore and a PCB layout company. Through early design involvement, controlled fabrication, rigorous testing, and continuous improvement, manufacturers deliver dependable PCB solutions that meet industry standards.

Contact MPN Tech for PCB solutions backed by expert layout support, strict quality control, and full compliance.